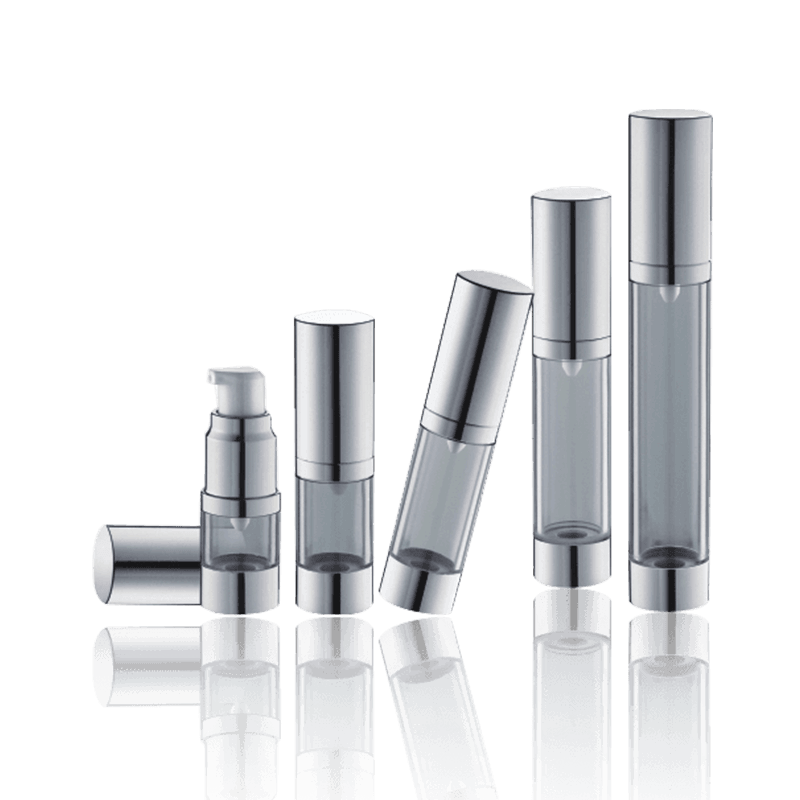

| Item No | Capacity | Diameter(∅) | Height |

| HY-004B-5ML | 5ML | 26mm | 85mm |

| HY-004B-10ML | 10ML | 26mm | 96mm |

| HY-004B-15ML | 15ML | 26mm | 110mm |

| HY-004B-20ML | 20ML | 26mm | 127mm |

| HY-004B-30ML | 30ML | 26mm | 157mm |

-

Choosing the right Cosmetic Cream Jar size is essential for both brand perception and product functionality. The size you select influences customer experience, product longevity, pricing strategy, and even shelf appeal. Understanding your product type, target audience, and packa......

READ MORE -

Cosmetic cream jars are essential elements in skincare routines, playing a significant role in both functionality and user experience. These jars, which house various creams and lotions, are designed with user-friendly features that aim to optimize how skincare products are used.......

READ MORE -

Cosmetic cream jars are essential packaging for a wide range of skincare and beauty products. The material choice for these jars not only affects the product's overall appearance but also plays a significant role in preserving the quality and shelf life of the cream inside. From ......

READ MORE -

When it comes to selecting the ideal cosmetic cream jar for skincare products, it's important to consider a range of factors. These jars serve not only as containers for creams and lotions but also play a significant role in preserving the product's effectiveness and enhancing th......

READ MORE

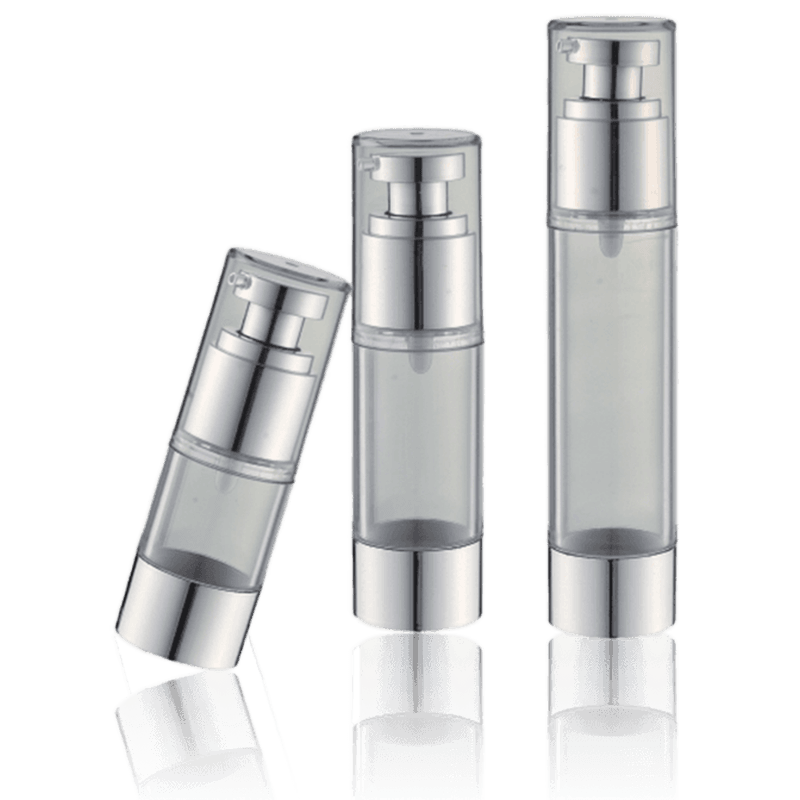

5ML-30ML cosmetic Airless Bottle-HS-004B has innovative features such as dual-mode intelligent access and visual scale design, which perfectly adapts to the needs of multiple scenarios from professional theaters to daily travel. 5ML-30ML cosmetic Airless Bottle-HS-004B has a replaceable inner core structure and carbon footprint optimization design, providing brands with the best solution that takes into account both efficacy preservation and environmental responsibility.

1. Differentiated core technology

Micro-pressure vacuum preservation system: Compared with traditional vacuum bottles, it adopts micro-pressure airtight technology, which adds an internal micro-positive pressure environment on the basis of complete sealing, further reducing the contact between the contents and the air, especially suitable for easily oxidized ingredients.

Anti-back-suction one-way valve: The innovative built-in one-way valve design ensures that there is no air backflow in the bottle after each press, eliminating the risk of pollution, and improving the hygiene by 40% compared with ordinary vacuum bottles.

2. Material and structure optimization

Lightweight glass + coating process: The bottle body is made of environmentally friendly materials and covered with a scratch-resistant matte coating, which takes into account both texture and drop resistance; the inner liner is upgraded to a medical-grade silicone seal ring, which is compatible with irritating ingredients such as acids (such as fruit acid and salicylic acid).

Transparent window model optional: Some models are equipped with a transparent scale bar on the side, which is convenient for users to observe the remaining amount in real time, suitable for treatment-type ampoule products.

3. Smart access experience

Click type: Precisely control the micro-liquid discharge, suitable for high-concentration essence.

Rotation lock: The pump head can be locked when traveling to prevent mis-pressure leakage, and pass civil aviation security inspection without worry.

Low resistance pump head: The special spring structure reduces the pressing force by 30%, improving the operating comfort of female users.

4. Segmented market positioning

Professional hospital products: meet the stringent requirements of medical and aesthetic post-repair products for sterile and pollution-free packaging.

Travel-friendly: The capacity below 30ml is designed for high-end small and medium-sized samples, replacing the pain points of traditional hose packaging that are easy to contaminate and difficult to squeeze out.

5. Sustainable innovation

Replaceable inner core design: supports the replacement package to be directly inserted into the bottle body to reduce the waste of the outer shell.

Carbon footprint optimization: This model reduces the use of plastic by 15% and has passed the life cycle assessment certification.

English

English 中文简体

中文简体