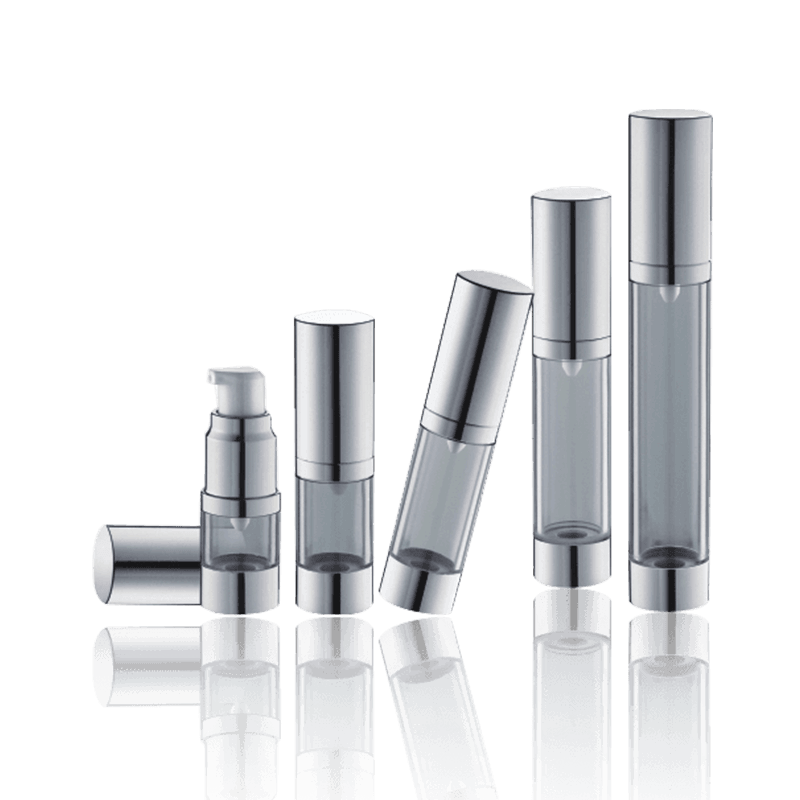

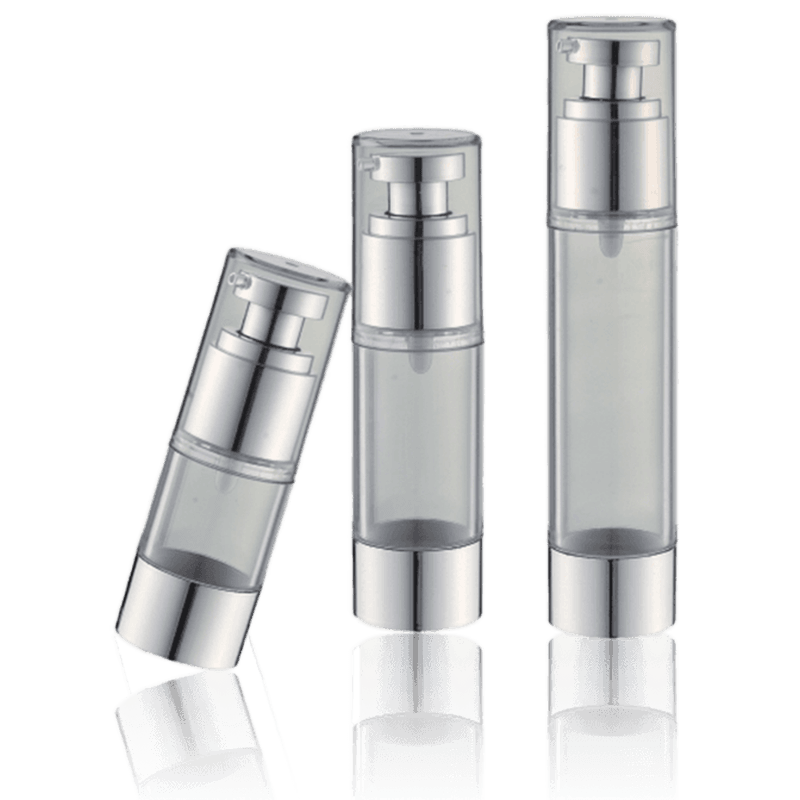

Liquid Distributor-HY24A-38

Get A Quote-

Choosing the right Cosmetic Cream Jar size is essential for both brand perception and product functionality. The size you select influences customer experience, product longevity, pricing strategy, and even shelf appeal. Understanding your product type, target audience, and packa......

READ MORE -

Cosmetic cream jars are essential elements in skincare routines, playing a significant role in both functionality and user experience. These jars, which house various creams and lotions, are designed with user-friendly features that aim to optimize how skincare products are used.......

READ MORE -

Cosmetic cream jars are essential packaging for a wide range of skincare and beauty products. The material choice for these jars not only affects the product's overall appearance but also plays a significant role in preserving the quality and shelf life of the cream inside. From ......

READ MORE -

When it comes to selecting the ideal cosmetic cream jar for skincare products, it's important to consider a range of factors. These jars serve not only as containers for creams and lotions but also play a significant role in preserving the product's effectiveness and enhancing th......

READ MORE

Streamlined pressing press cosmetic Pump Liquid Distributor-HY24A-38 perfectly combines engineering aesthetics and functionalism: vacuum sealing technology locks in the freshness of ingredients, the adjustable discharging system is suitable for different textures, and the leak-proof streamlined shape takes into account portability and elegance. Whether it is a high-end anti-aging cream or a lady-level lotion, it can deliver in a stable and hygienic way, allowing users to feel the brand's ultimate pursuit of details from the first press.

1. Product positioning and core advantages

Precise use: specially designed for high-viscosity skin care products, a single press quantitative discharging is achieved through a precision spring and piston structure to avoid waste.

Hygiene protection: the fully sealed design blocks air and bacteria, prolongs the shelf life of the active ingredients in the contents, and meets the cosmetics GMP standards.

Anti-leakage technology: the one-way valve + vacuum back suction structure is adopted, and the liquid does not flow back when tilted or inverted, which is suitable for travel and mobile scenes.

2. Differentiation highlights

Flow adjustment function: the rotating pump head can adjust the discharging amount to meet the needs of users from light lotions to heavy creams.

Streamlined ergonomics: 45° inclined pressing surface + anti-slip texture design, fits the fingertips to reduce fatigue after long-term use.

Brand customization: supports LOGO laser engraving and color matching to enhance brand recognition.

3. Industry application trends

Green and environmentally friendly: detachable structure design, easy to recycle and classify, in line with the EU REACH regulations on recyclable packaging requirements.

High-end matching: with vacuum bottles and dropper bottles to form an "active ingredient preservation kit", it has become the standard for anti-aging/whitening products.

Streamlined pressing press cosmetic Pump Liquid Distributor-HY24A-38 represents the upgrade of skin care packaging materials to the direction of "precision, preservation, and interaction", and its technical details can become a value-added point for brand product promotion.

English

English 中文简体

中文简体