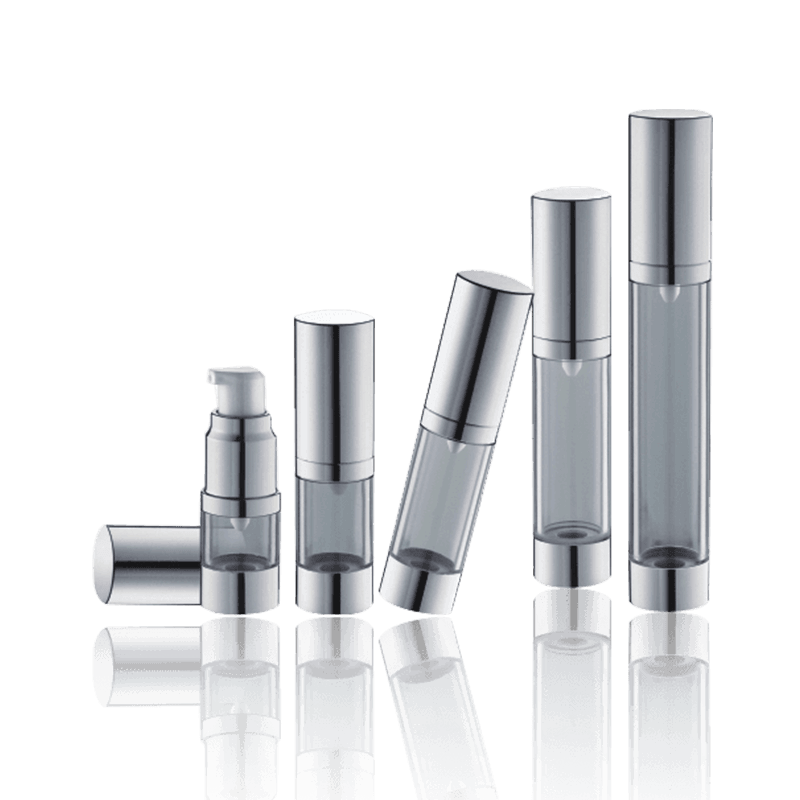

| Item No | Capacity | Diameter(∅) | Height |

| HY-007A- 15ML | 15ML | 33mm | 97mm |

| HY-007A- 30ML | 30ML | 33mm | 118mm |

| HY-007A- 50ML | 50ML | 33mm | 150mm |

-

Choosing the right Cosmetic Cream Jar size is essential for both brand perception and product functionality. The size you select influences customer experience, product longevity, pricing strategy, and even shelf appeal. Understanding your product type, target audience, and packa......

READ MORE -

Cosmetic cream jars are essential elements in skincare routines, playing a significant role in both functionality and user experience. These jars, which house various creams and lotions, are designed with user-friendly features that aim to optimize how skincare products are used.......

READ MORE -

Cosmetic cream jars are essential packaging for a wide range of skincare and beauty products. The material choice for these jars not only affects the product's overall appearance but also plays a significant role in preserving the quality and shelf life of the cream inside. From ......

READ MORE -

When it comes to selecting the ideal cosmetic cream jar for skincare products, it's important to consider a range of factors. These jars serve not only as containers for creams and lotions but also play a significant role in preserving the product's effectiveness and enhancing th......

READ MORE

15ML 30ML 50ML glass Airless Bottle for cosmetics HS-007A Redefines the preservation standard of active skin care products with the pure genes of glass and the technological blood of vacuum.

1. Vacuum sealing system

Zero air contact design: Through the bottom piston mechanism, negative pressure is formed in the bottle when the pump head is pressed, pushing the piston up to discharge the contents, while completely isolating oxygen, bacteria and pollutants.

Active ingredient protection: Especially suitable for high-end skin care products with easily oxidized ingredients, avoiding photosensitive degradation and prolonging the stability of active ingredients.

Full dose use: The residual rate is less than 0.5%, significantly reducing waste.

2. Glass material advantages

Chemical inertness: Made of glass, it does not react with the contents, is non-toxic and odorless, and is resistant to high temperature sterilization and low temperature storage.

Transparency and light protection: High light transmittance makes it easy to observe the remainder, and the dark glass option provides UV shielding to protect photosensitive ingredients.

3. Environmentally friendly design: Glass material is recyclable, meets EU regulations and certification requirements, and has a carbon footprint that is 30% lower than mixed materials.

4. Common usage problems and solutions

The pump head is difficult to press: the piston is stuck or the vacuum fails, and it is necessary to check whether the small hole at the bottom of the bottle is leaking.

Delay in first discharge: It is normal to press 2-3 times in a row to empty the air in the pump chamber at the beginning.

Remaining amount visibility: Transparent bottles are less light-proof than dark bottles. It is recommended to use 7-8g spare packs to solve the problem of remaining amount estimation.

15ML 30ML 50ML glass Airless Bottle for cosmetics HS-007A is a typical model of 15-50mL glass vacuum bottles. Its core competitiveness lies in:

Scientific preservation (vacuum + glass double barrier to extend the life of active ingredients)

High-end texture (transparency and customized process to enhance brand influence)

Green compliance (all recycled materials are compatible with global environmental regulations)

English

English 中文简体

中文简体

-1.png)