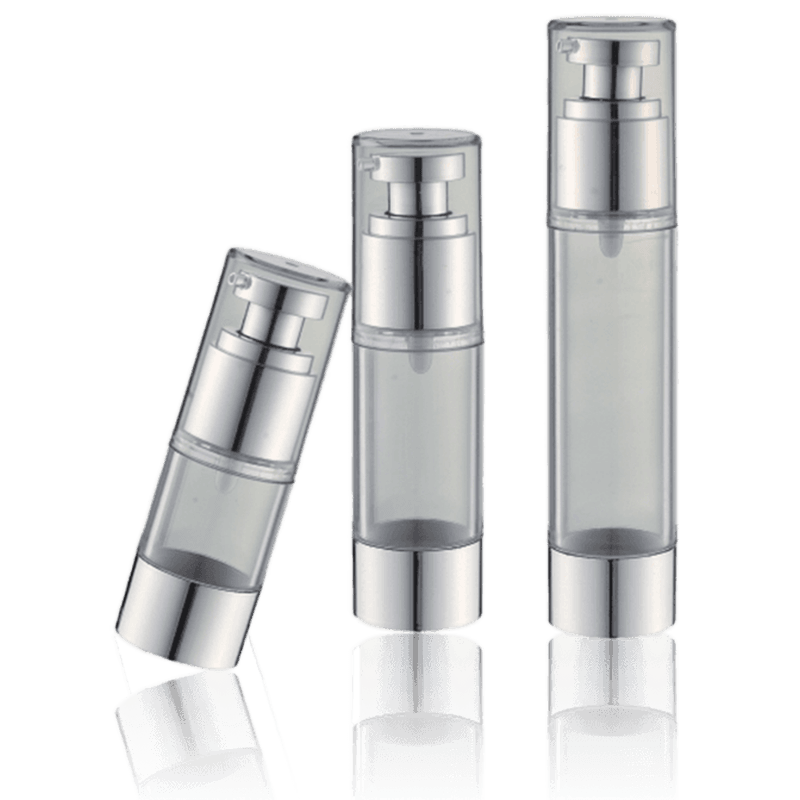

| SIZE: | ∅20/410 |

| QTY: | 5000PCS |

| MEAS: | 57x32x38CM |

-

Choosing the right Cosmetic Cream Jar size is essential for both brand perception and product functionality. The size you select influences customer experience, product longevity, pricing strategy, and even shelf appeal. Understanding your product type, target audience, and packa......

READ MORE -

Cosmetic cream jars are essential elements in skincare routines, playing a significant role in both functionality and user experience. These jars, which house various creams and lotions, are designed with user-friendly features that aim to optimize how skincare products are used.......

READ MORE -

Cosmetic cream jars are essential packaging for a wide range of skincare and beauty products. The material choice for these jars not only affects the product's overall appearance but also plays a significant role in preserving the quality and shelf life of the cream inside. From ......

READ MORE -

When it comes to selecting the ideal cosmetic cream jar for skincare products, it's important to consider a range of factors. These jars serve not only as containers for creams and lotions but also play a significant role in preserving the product's effectiveness and enhancing th......

READ MORE

Precision closing cosmetic cosmetic Butterfly Cap-HY-F02 is a precision hinged cover designed for high-end cosmetic packaging. It adopts a butterfly-style opening and closing structure to ensure precise alignment and sealing when closed. It is mainly used in cosmetic products such as powder boxes, blush boxes, eyeshadow palettes, etc., combining functionality and aesthetics.

1. Core Features

Precision closure: The hinge structure is precisely calculated to ensure that the lid and the box body are completely matched to avoid powder leakage or drying due to misalignment.

Butterfly design: Smooth opening and closing, light feel, and improved user experience; elegant appearance, suitable for mid-to-high-end cosmetic brands.

Material diversity: ABS, metal alloys or environmentally friendly plastics are usually used, and the surface can be electroplated, sprayed or inlaid for decoration.

Sealing optimization: Some models have built-in silicone sealing rings to enhance moisture resistance and extend the shelf life of cosmetics.

2. In terms of structural design, HY-F02 uses a double-hinge symmetrical structure to make the opening action soft and smooth, and has a certain damping feeling, which can prevent automatic opening due to shaking or accidental falling, thereby effectively protecting the internal cosmetics from contamination and damage. This product widely uses ABS, AS or environmentally friendly PCR materials, which not only meets the requirements of durability and transparency, but also fits the current cosmetics industry's focus on sustainable materials.

From a production perspective, the precise closing structure used by HY-F02 requires strict injection molding tolerance control, and usually achieves stable mass production through high-precision steel molds and automated assembly lines. This type of "precise closure + beautiful opening and closing" butterfly cover design is increasingly favored by European and American markets, Japanese and Korean brands, and emerging domestic brands, and has become an important component to enhance brand packaging quality and user experience.

English

English 中文简体

中文简体