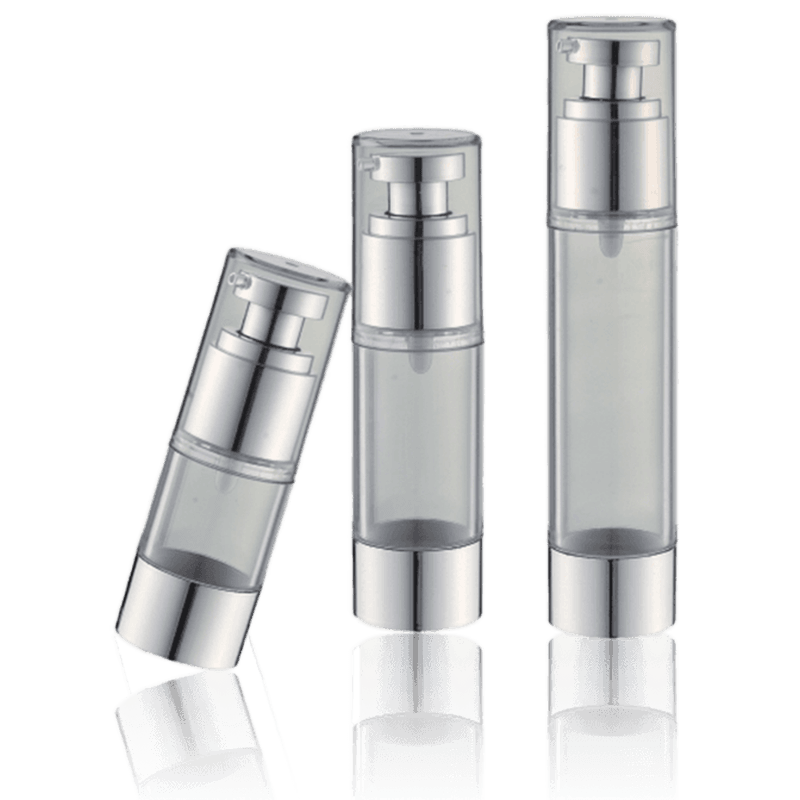

| Item No | Capacity | Diameter(∅) | Height |

| HS-001A- -5ML | 5ML | 20mm | 72.5mm |

| HS-001A- 10ML | 10ML | 20mm | 82. 5mm |

| HS-001A- 15ML | 15ML | 20mm | 97mm |

-

Choosing the right Cosmetic Cream Jar size is essential for both brand perception and product functionality. The size you select influences customer experience, product longevity, pricing strategy, and even shelf appeal. Understanding your product type, target audience, and packa......

READ MORE -

Cosmetic cream jars are essential elements in skincare routines, playing a significant role in both functionality and user experience. These jars, which house various creams and lotions, are designed with user-friendly features that aim to optimize how skincare products are used.......

READ MORE -

Cosmetic cream jars are essential packaging for a wide range of skincare and beauty products. The material choice for these jars not only affects the product's overall appearance but also plays a significant role in preserving the quality and shelf life of the cream inside. From ......

READ MORE -

When it comes to selecting the ideal cosmetic cream jar for skincare products, it's important to consider a range of factors. These jars serve not only as containers for creams and lotions but also play a significant role in preserving the product's effectiveness and enhancing th......

READ MORE

5ML 10ML 15ML Precise quantity control Airless Bottle-HS-001A With breakthrough vacuum preservation technology and intelligent dosage control, it completely solves the pain points of the industry and becomes an ideal packaging solution for high-active ingredient skin care products, ampoule essences and professional repair products.

1. Core technology: vacuum preservation system

Zero oxygen seal: adopts a one-way air pressure design, isolates the air through the vacuum diaphragm, prevents the product from contacting with oxygen, prevents the oxidation and inactivation of active ingredients (such as vitamin C, peptides, etc.), and improves the preservation efficiency.

Aseptic barrier: medical-grade liner material combined with spring back pressure mechanism to avoid bacterial reflux and meet the hygiene standards of cosmetics.

2. Precise quantity control design

Micro-metering pump technology: quantitative output every time it is pressed, 5ML/10ML/15ML specifications are suitable for high-value products such as essences, ampoules, high-concentration stock solutions, and reduce waste.

Full emptying structure: the suspended piston at the bottom of the bottle rises with the amount used, ensuring that more than 99% of the product can be completely used up, solving the problem of residual in traditional bottles and cans.

3. User experience upgrade

Anti-pollution access: The push-type one-way outlet avoids finger contact and reduces the risk of secondary contamination. It is especially suitable for sensitive skin care products and medical and cosmetic post-operative repair products.

Lightweight material: Aviation aluminum/glass outer bottles are optional, with vacuum liner, portable and light-proof, extending the life of photosensitive ingredients.

4. Industry application scenarios

High-end skin care: Suitable for easily degradable ingredients such as antioxidant essence, hyaluronic acid stock solution, freeze-dried powder compound solution.

Professional medical beauty: Cooperate with water light needle and microneedle postoperative repair products to ensure precise dosage control in a sterile environment.

Green packaging trend: The detachable and replaceable inner core design reduces plastic waste and complies with EU environmental regulations.

5. Market competitiveness

Laboratory data: Compared with ordinary bottles and jars, the vacuum bottle HS-001A can extend the shelf life of the product by 6~12 months, and the active retention rate after opening is increased by 65%.

English

English 中文简体

中文简体

-1.png)