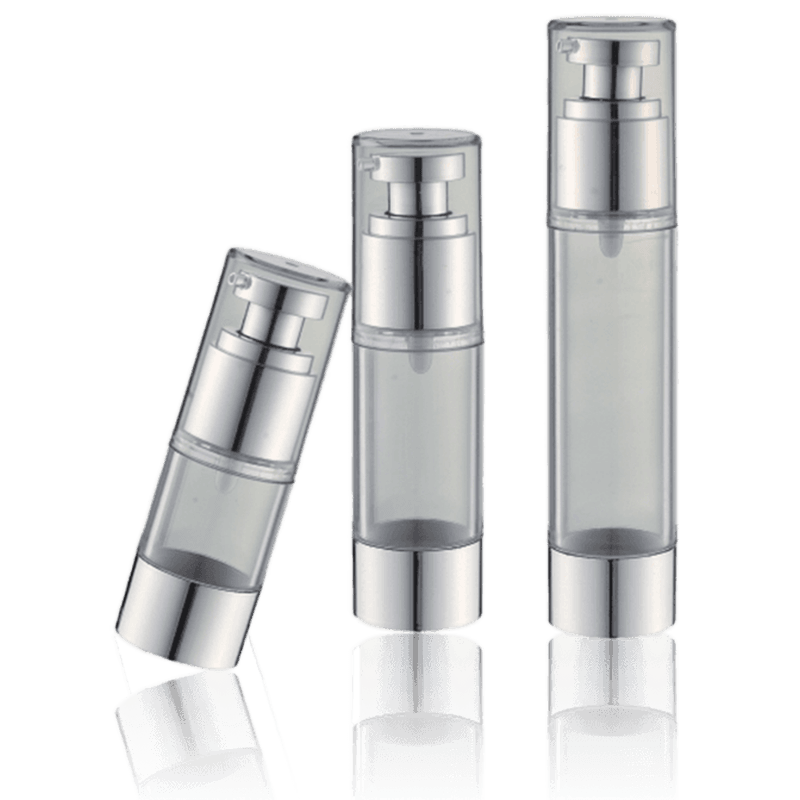

| Item No | Capacity | Diameter(∅) | Height |

| HY-017C-50ML | 50ML | 41.5mm | 117mm |

| HY-017C-80ML | 80ML | 41.5mm | 144mm |

| HY-017C-100ML | 100ML | 41.5mm | 161mm |

| HY-017C-120ML | 120ML | 41.5mm | 198mm |

-

Choosing the right Cosmetic Cream Jar size is essential for both brand perception and product functionality. The size you select influences customer experience, product longevity, pricing strategy, and even shelf appeal. Understanding your product type, target audience, and packa......

READ MORE -

Cosmetic cream jars are essential elements in skincare routines, playing a significant role in both functionality and user experience. These jars, which house various creams and lotions, are designed with user-friendly features that aim to optimize how skincare products are used.......

READ MORE -

Cosmetic cream jars are essential packaging for a wide range of skincare and beauty products. The material choice for these jars not only affects the product's overall appearance but also plays a significant role in preserving the quality and shelf life of the cream inside. From ......

READ MORE -

When it comes to selecting the ideal cosmetic cream jar for skincare products, it's important to consider a range of factors. These jars serve not only as containers for creams and lotions but also play a significant role in preserving the product's effectiveness and enhancing th......

READ MORE

50ML-120ML Purple gradient Airless Cosmetic Bottle-HS-017C is a high-end packaging solution that combines aesthetics and functionality, designed for high-value skin care products such as essences, lotions, and sunscreens. Its unique purple gradient appearance gives the product a sense of luxury and technology, while the vacuum pump system ensures the freshness and precise use of the contents, effectively enhancing the brand image and enhancing the consumer experience.

1. Core features of the product

Capacity range: 50ML-120ML, suitable for mid-to-high-end essences, lotions, sunscreens or pre-makeup products, meeting consumers' needs for portability and durability.

Purple gradient design: Gradient color is a popular trend in current cosmetic packaging. Purple symbolizes luxury, mystery and technology, and is suitable for anti-aging, whitening or night repair products.

The process uses spray gradient or multi-layer injection molding, and the color fastness must be ensured to meet industry standards.

Vacuum pump system: isolate the air, prevent oxidation of ingredients, reduce the addition of preservatives; accurately control the amount to avoid waste.

2. Material and safety standards

Bottle material:

PETG/AS: high transparency, chemical resistance, suitable for gradient effect display. PP: used for vacuum pump components, in line with food grade or pharmaceutical grade standards.

Environmental requirements: recyclable, PETG is more environmentally friendly than ordinary PET.

3. Market application and trend

Target categories:

High-end essence, ampoule, VC derivative products.

Emerging concept products such as microecological skin care, pure beauty.

Consumer preferences:

Purple gradient enhances shelf appeal and is suitable for social media communication.

Sustainable upgrade, using replaceable liner design.

English

English 中文简体

中文简体