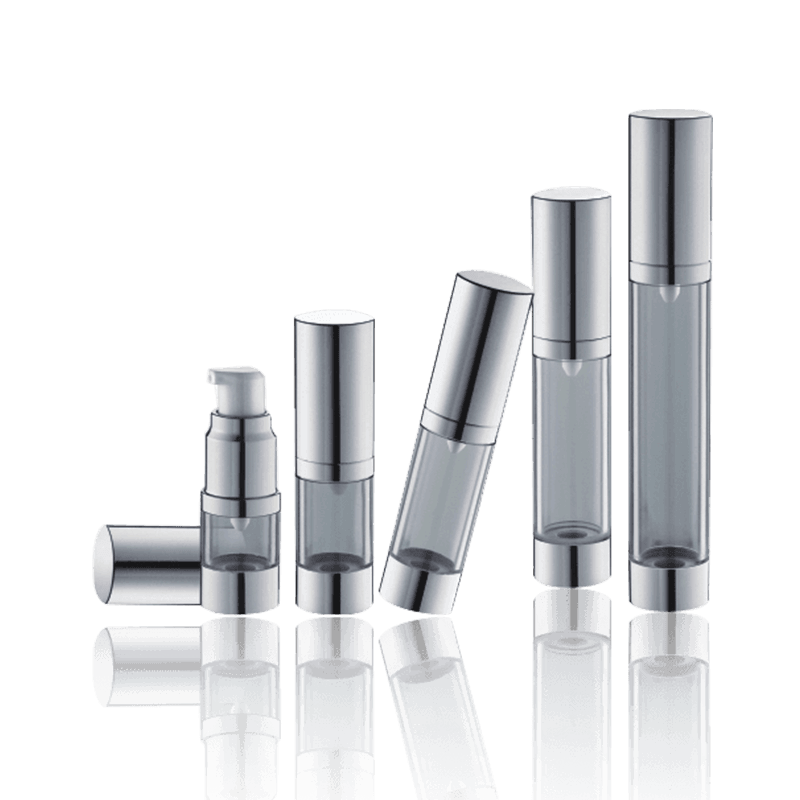

| Item No | Capacity | Diameter(∅) | Height |

| HS-017B-50ML | 50ML | 41.5mm | 120mm |

| HS-017B-80ML | 80ML | 41.5mm | 147mm |

| HS-017B-100ML | 100ML | 41.5mm | 164mm |

| HS-017B-120ML | 120ML | 41.5mm | 183mm |

-

Choosing the right Cosmetic Cream Jar size is essential for both brand perception and product functionality. The size you select influences customer experience, product longevity, pricing strategy, and even shelf appeal. Understanding your product type, target audience, and packa......

READ MORE -

Cosmetic cream jars are essential elements in skincare routines, playing a significant role in both functionality and user experience. These jars, which house various creams and lotions, are designed with user-friendly features that aim to optimize how skincare products are used.......

READ MORE -

Cosmetic cream jars are essential packaging for a wide range of skincare and beauty products. The material choice for these jars not only affects the product's overall appearance but also plays a significant role in preserving the quality and shelf life of the cream inside. From ......

READ MORE -

When it comes to selecting the ideal cosmetic cream jar for skincare products, it's important to consider a range of factors. These jars serve not only as containers for creams and lotions but also play a significant role in preserving the product's effectiveness and enhancing th......

READ MORE

50ML-120ML Airless Bottle Travel Bottles Lotion Dispenser HS-017B is a packaging container that uses the principle of air pressure difference to achieve content access. It can effectively isolate the air, prevent oxidation and pollution, and is suitable for skin care products such as lotions and essences.

1. Core technical principles and structural design

Vacuum mechanism:

Air pressure drive principle: The low pressure in the bottle is formed through the one-way seal of the pump group, and the bottom piston is pushed up by atmospheric pressure to discharge the contents upward. The friction between the piston and the bottle wall needs to be precisely controlled-too tight will cause difficulty in pressing, and too loose will cause leakage.

Anti-pollution advantages: Completely isolate air contact, reduce oxidation and deterioration and microbial growth, reduce the need for preservatives, and extend the shelf life of the product.

Precise quantitative control:

After the pump group diameter stroke and elastic force parameters are fixed, the error of each press can be controlled within ±0.05ml, which is suitable for products that require precise dosage such as essence lotions.

Typical structural components:

Core components: outer cover pump group (including spring/valve), large piston bottom support of bottle body (with air vent at the bottom).

Classification:

Structural type: ordinary single bottle, composite double bottle.

Appearance design: cylindrical, square oval, with a capacity of 50ml-120ml.

2.Material and manufacturing process points

Mainstream material application

Plastic dominance: taking into account both lightweight and chemical stability.

Process barriers

Injection molding accuracy: The gap between the piston and the bottle body needs to be controlled at the micron level, relying on professional molds.

Filling requirements: Special low-speed vacuum filling machine to extract air, tilting or high-speed filling can easily cause displacement and leakage of the inner plug.

3.Market positioning and industry trends

Core application scenarios:

Applicable categories: essence, lotion, low-viscosity cream (must be fluid and particle-free).

Vacuum bottles have become the mainstream packaging for mid-to-high-end skin care products due to their sealing and user experience.

English

English 中文简体

中文简体