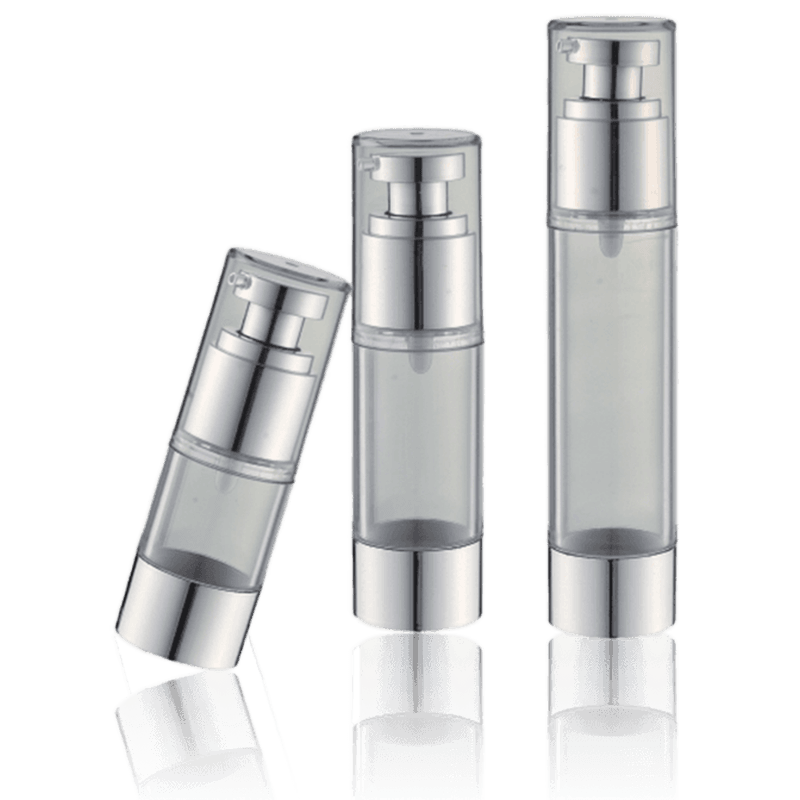

| Item No | Capacity | Diameter(∅) | Height |

| HS-003A- -5ML | 5ML | 18mm | 74mm |

| HS-003A- 10ML | 10ML | 18mm | 95mm |

| HS-003A- 15ML | 15ML | 18mm | 130mm |

-

Choosing the right Cosmetic Cream Jar size is essential for both brand perception and product functionality. The size you select influences customer experience, product longevity, pricing strategy, and even shelf appeal. Understanding your product type, target audience, and packa......

READ MORE -

Cosmetic cream jars are essential elements in skincare routines, playing a significant role in both functionality and user experience. These jars, which house various creams and lotions, are designed with user-friendly features that aim to optimize how skincare products are used.......

READ MORE -

Cosmetic cream jars are essential packaging for a wide range of skincare and beauty products. The material choice for these jars not only affects the product's overall appearance but also plays a significant role in preserving the quality and shelf life of the cream inside. From ......

READ MORE -

When it comes to selecting the ideal cosmetic cream jar for skincare products, it's important to consider a range of factors. These jars serve not only as containers for creams and lotions but also play a significant role in preserving the product's effectiveness and enhancing th......

READ MORE

In the field of modern cosmetic packaging, 5ML 10ML 15ML mini Airless pump Bottle-HS-003A is gradually becoming the preferred packaging solution for mid-to-high-end skin care products and professional functional cosmetics, especially the small capacity and easy-to-carry mini specifications (such as 5ML, 10ML, 15ML) are increasingly favored by brands and consumers.

1. Principles and advantages of vacuum bottles

The vacuum pump bottle realizes the "zero air contact" extraction method through the piston design, effectively isolating the air and preventing external bacteria, oxides or moisture from entering the bottle. Compared with traditional pump bottles or open bottles, vacuum bottles have obvious advantages in the following aspects:

High sealing: extend the shelf life of the product and reduce the amount of preservatives;

Precise dosage control: the output is consistent each time you press to avoid waste;

Reduce reflux pollution: prevent secondary pollution caused by air reflux after use;

Continuous and stable output: even if the liquid in the bottle is close to the end, it can be discharged smoothly.

2. Rise of market demand for mini-capacity

As consumers’ preference for “portable skin care”, “packaging for travel” and “on-demand purchase” increases, small-capacity vacuum pump bottles have emerged, which are particularly suitable for the following usage scenarios:

Travel/carry-on: 5ML-15ML capacity is adapted to aircraft security standards and is easy to carry;

Trial/experience pack: allows users to try high-end products at low cost before purchasing;

Highly concentrated products: such as eye cream and essence, usually only need to be used in small amounts;

Customized skin care: meets the packaging needs of precise formulas for different people and skin types.

3. Environmental protection trends promote the development of vacuum packaging

Today, when sustainable development has become an industry consensus, vacuum bottles are also constantly moving closer to environmental protection in terms of material selection and structural design. Recyclable and environmentally friendly plastics are mostly used, the bottle body is light, easy to recycle and reuse, and caters to the brand’s green packaging needs.

4. Technology and quality are the key

Although the structure seems simple, a high-quality vacuum pump bottle must meet the following requirements:

The gap between the piston and the bottle wall is extremely small but does not stick to each other, ensuring smooth pumping;

The bottle mouth and the pump head are precisely matched to prevent leakage and blockage;

No jamming or continuous flow after multiple presses, reflecting the elasticity and resilience of the pump head;

Compatible with a variety of paste/liquid textures, maintaining a good distribution state.

English

English 中文简体

中文简体