-

Choosing the right Cosmetic Cream Jar size is essential for both brand perception and product functionality. The size you select influences customer experience, product longevity, pricing strategy, and even shelf appeal. Understanding your product type, target audience, and packa......

READ MORE -

Cosmetic cream jars are essential elements in skincare routines, playing a significant role in both functionality and user experience. These jars, which house various creams and lotions, are designed with user-friendly features that aim to optimize how skincare products are used.......

READ MORE -

Cosmetic cream jars are essential packaging for a wide range of skincare and beauty products. The material choice for these jars not only affects the product's overall appearance but also plays a significant role in preserving the quality and shelf life of the cream inside. From ......

READ MORE -

When it comes to selecting the ideal cosmetic cream jar for skincare products, it's important to consider a range of factors. These jars serve not only as containers for creams and lotions but also play a significant role in preserving the product's effectiveness and enhancing th......

READ MORE

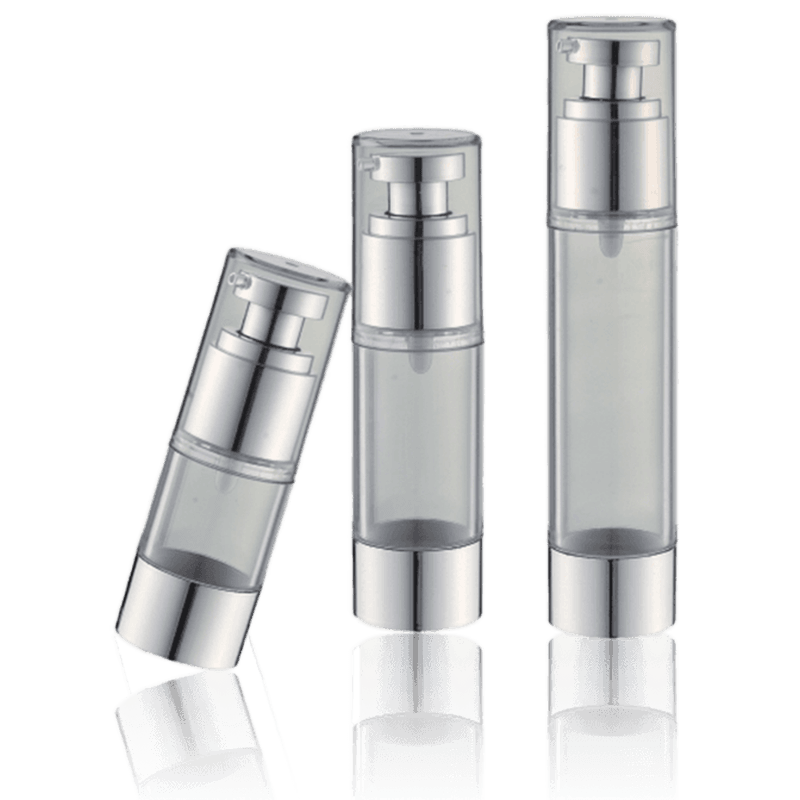

Strong seal cosmetic pump head Liquid Distributor-HY24B-21 is a cosmetic pump head designed for high sealing requirements. It is suitable for skin care products with easily oxidized, volatile or highly active ingredients (such as essences, ampoules, essential oils, etc.). The pump head adopts a multiple sealing structure to ensure the long-term stability of the contents, prevent air backflow and liquid leakage, and extend the shelf life of the product.

1. Core process features

Strengthened sealing technology: Double/triple sealing structure: combined with silicone gasket, inner plug seal and thread locking design, it effectively isolates air and moisture.

Vacuum anti-backflow: special valve core design, automatically closed after pressing, to prevent external air from entering the bottle.

Material optimization: The main body is made of corrosion-resistant PP or PETG, and the seal is made of food-grade silicone, which is compatible with volatile ingredients such as alcohols and essential oils.

Precise liquid discharge: micron-level precision mold molding ensures stable output each time it is pressed, suitable for high-priced products.

2. Key performance parameters

Sealing level: no leakage through negative pressure test, far exceeding industry standards.

Applicable liquids: Suitable for low-viscosity to medium-high-viscosity liquids, such as essences, oils, and aqueous solutions.

Compatible with wide-mouth glass bottles, PET bottles, etc., suitable for cold chain transportation or storage in high-temperature environments.

3. Industry application trends

Active ingredient protection: used for packaging of easily oxidized ingredients such as VC and retinol to reduce inactivation.

High-end market positioning: surface treatments such as electroplating metal luster and matte texture improve product grade.

Sustainable design: detachable structure is easy to recycle, and some brands use bio-based plastics to reduce carbon footprint.

5. Target customers and scenarios

High-efficacy skin care products: ampoules, disposable essences, and antioxidant products.

Essential oils/aromatherapy products: high-concentration essential oils that need to be strictly prevented from volatilization.

Medical-grade packaging: medical beauty repair products, aseptic formula requirements.

Strong seal cosmetic pump head Liquid Distributor-HY24B-21 uses technology to drive freshness, solves the core pain points of highly active cosmetics at the packaging end, and becomes the preferred solution for functional skin care brands to upgrade packaging. In the future, as consumers pay more attention to the freshness and efficacy of products, the combination of smart sealing and environmentally friendly materials will further expand its application scenarios.

English

English 中文简体

中文简体