-

Choosing the right Cosmetic Cream Jar size is essential for both brand perception and product functionality. The size you select influences customer experience, product longevity, pricing strategy, and even shelf appeal. Understanding your product type, target audience, and packa......

READ MORE -

Cosmetic cream jars are essential elements in skincare routines, playing a significant role in both functionality and user experience. These jars, which house various creams and lotions, are designed with user-friendly features that aim to optimize how skincare products are used.......

READ MORE -

Cosmetic cream jars are essential packaging for a wide range of skincare and beauty products. The material choice for these jars not only affects the product's overall appearance but also plays a significant role in preserving the quality and shelf life of the cream inside. From ......

READ MORE -

When it comes to selecting the ideal cosmetic cream jar for skincare products, it's important to consider a range of factors. These jars serve not only as containers for creams and lotions but also play a significant role in preserving the product's effectiveness and enhancing th......

READ MORE

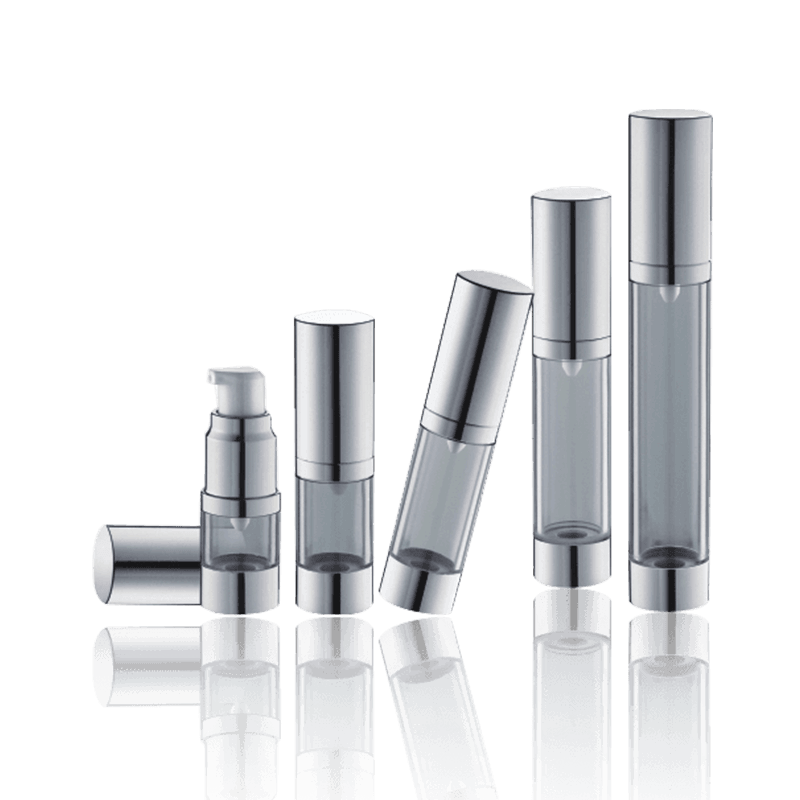

Aseptic design Cream Box Series-PJ-002H is an aseptic packaging container designed for high-end cream cosmetics (such as face cream, eye cream, essence cream), suitable for skin care brands with strict requirements on hygiene, antioxidant and product preservation. With the growing demand of consumers for "pollution-free, low preservative" products, aseptic design has become one of the core trends of cosmetic packaging, especially for sensitive skin care, medical beauty products or natural organic brands.

1. Key design features

Aseptic barrier system

Sealing technology: The inner liner isolation design is adopted to prevent the paste from contacting with the outside world and prevent microbial contamination.

Anti-backflow structure: Some models may be equipped with a one-way discharge device to prevent the paste from backflowing and contaminating the contents during use.

Material safety and compatibility

Main material: Medical grade PP or PETG is usually selected, which has high chemical stability and does not react with the paste.

Inner liner/coating: Some versions may add antibacterial coating or light-proof material to protect photosensitive ingredients.

User experience optimization

Precise dosage: The single dosage is controlled by vacuum pump or press-type design to reduce waste.

Anti-pollution design: The wide-mouth bottle can be equipped with a spoon slot to prevent fingers from directly contacting the cream.

2. Industry compliance standards

Meet the requirements of good manufacturing practices for cosmetics on packaging cleanliness.

Ensure material safety and prevent harmful substances from migrating to the cream.

Sustainable development: Recyclable materials or replaceable liner design, in line with environmental regulations.

3. Application scenarios and differences with competing products

Target products: high-active ingredients, preservative-free formulas or high-priced creams.

Differentiation advantage: Compared with traditional wide-mouth bottles, Aseptic design Cream Box Series-PJ-002H reduces preservative dependence through physical barriers and extends the shelf life after opening.

The aseptic design of Aseptic design Cream Box Series-PJ-002H is in line with the triple upgrade direction of "safety + efficacy + sustainability" in the cosmetics industry, especially suitable for emerging clean beauty (Clean Beauty) and functional skin care brands, helping customers increase product added value and reduce after-sales risks.

English

English 中文简体

中文简体